MULTIAXIALS MADE IN AMERICA

SOURCED RESPONSIBLY.

PRICED COMPETITIVELY.

Made in America

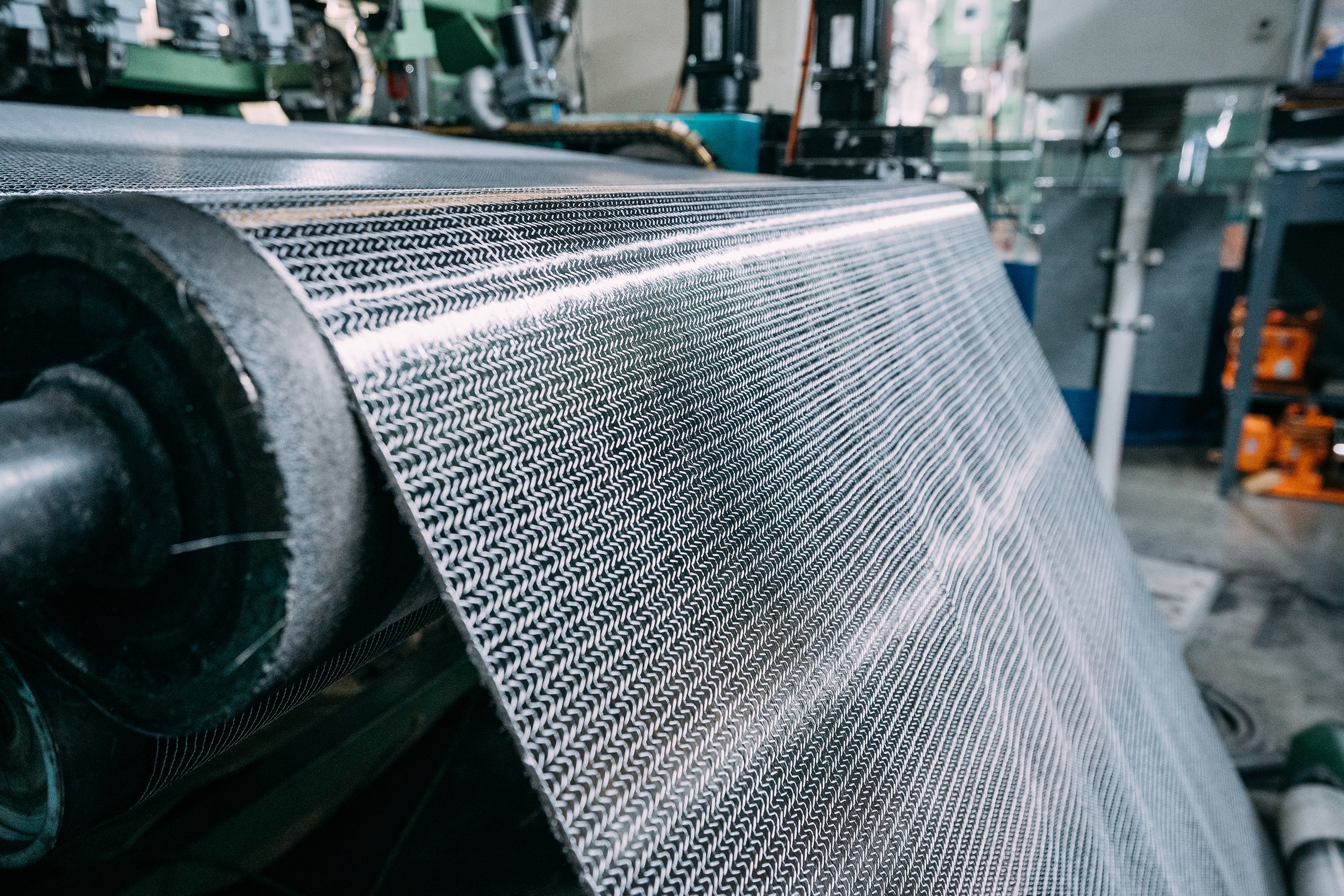

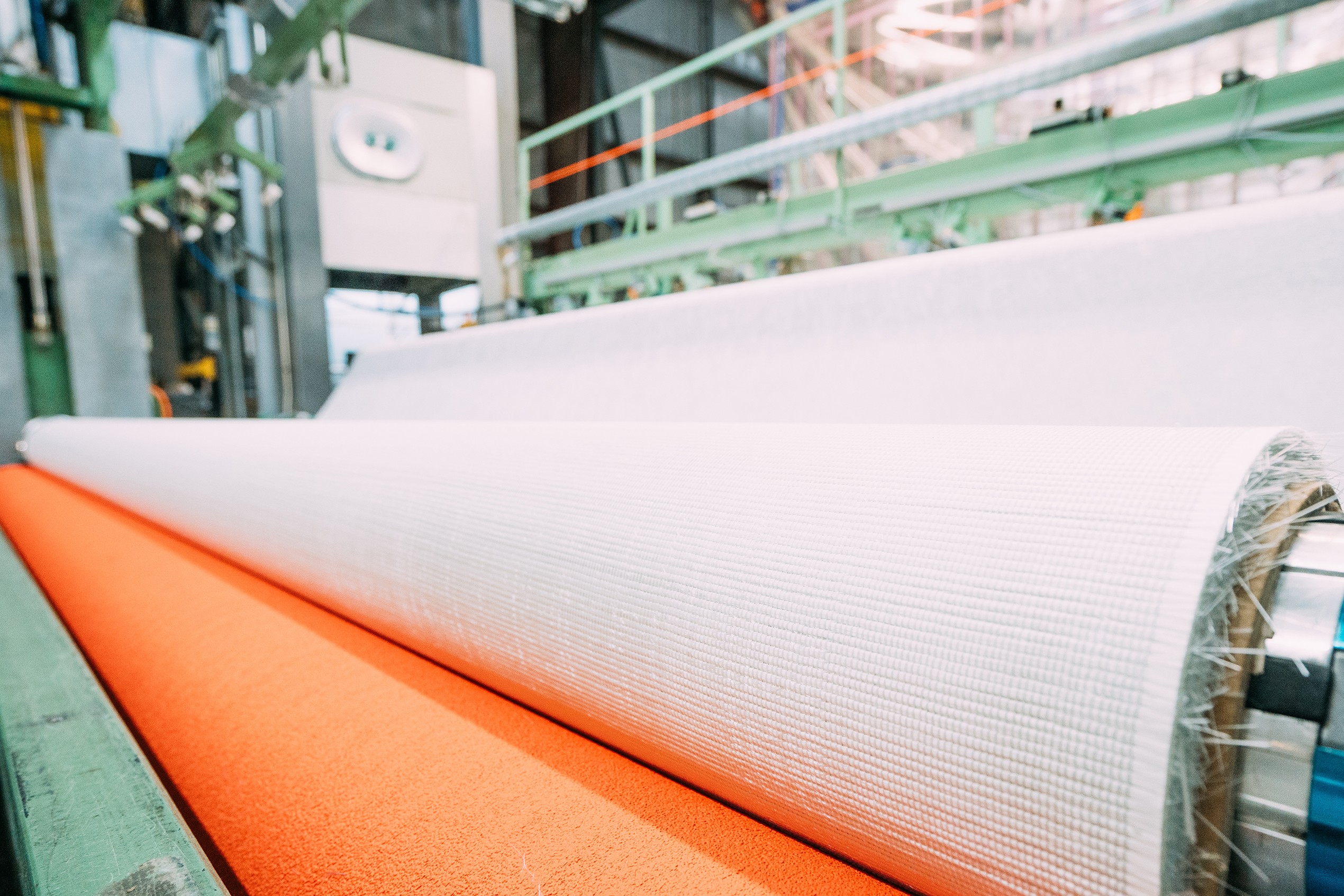

As the leading manufacturer of multiaxial fabrics, SAERTEX USA combines local production with decades of global composite expertise. At our site in Huntersville, North Carolina, we manufacture high-performance reinforcement materials for demanding composite applications - made in America for the North American market.

- Local production in North Carolina: Close to our customers for faster lead times, high flexibility and on-site technical support backed by the global SAERTEX network.

- Immediate availability: Ready-to-ship Standard Glass and Carbon product lines with uncompromised quality.

- Tailored reinforcement solutions: Lightweight, customizable fabrics designed for your specific application.

- Up to 150": Extra-wide fabrics that increase efficiency and reduce layup time in your production process.

With SAERTEX USA, you get high-quality textile solutions made in America that fit your needs – supported by the global experience and reliability of the SAERTEX Group.

Huntersville, NC

- Production: since 2001

- Manufacturing area: over 107.000 ft2

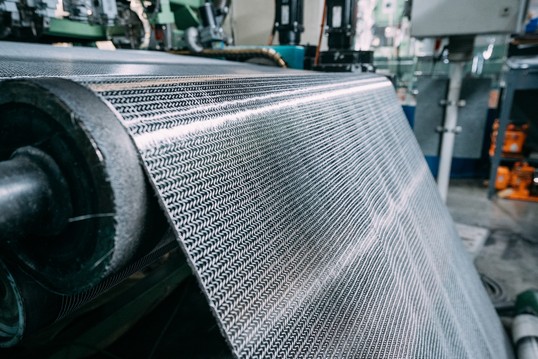

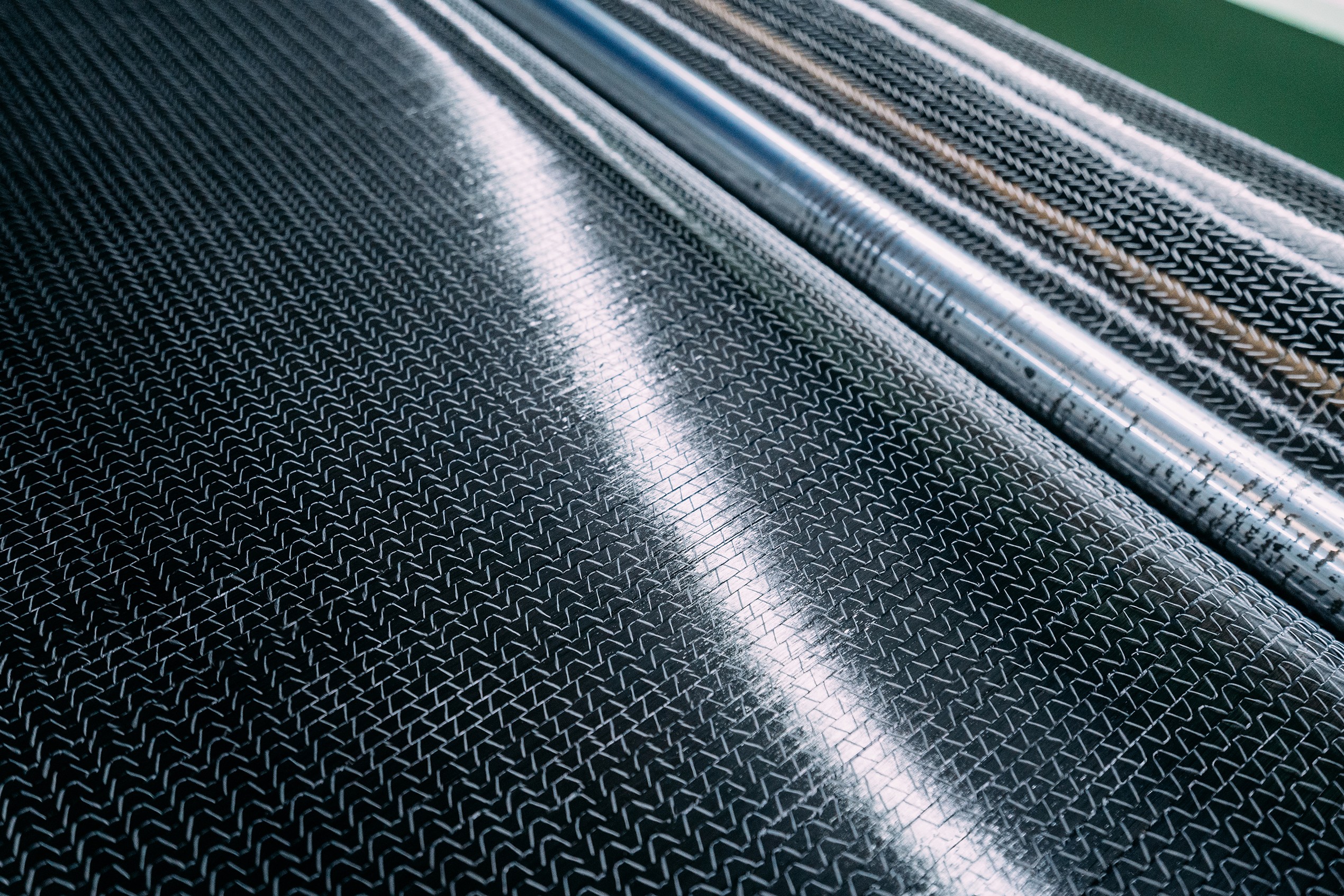

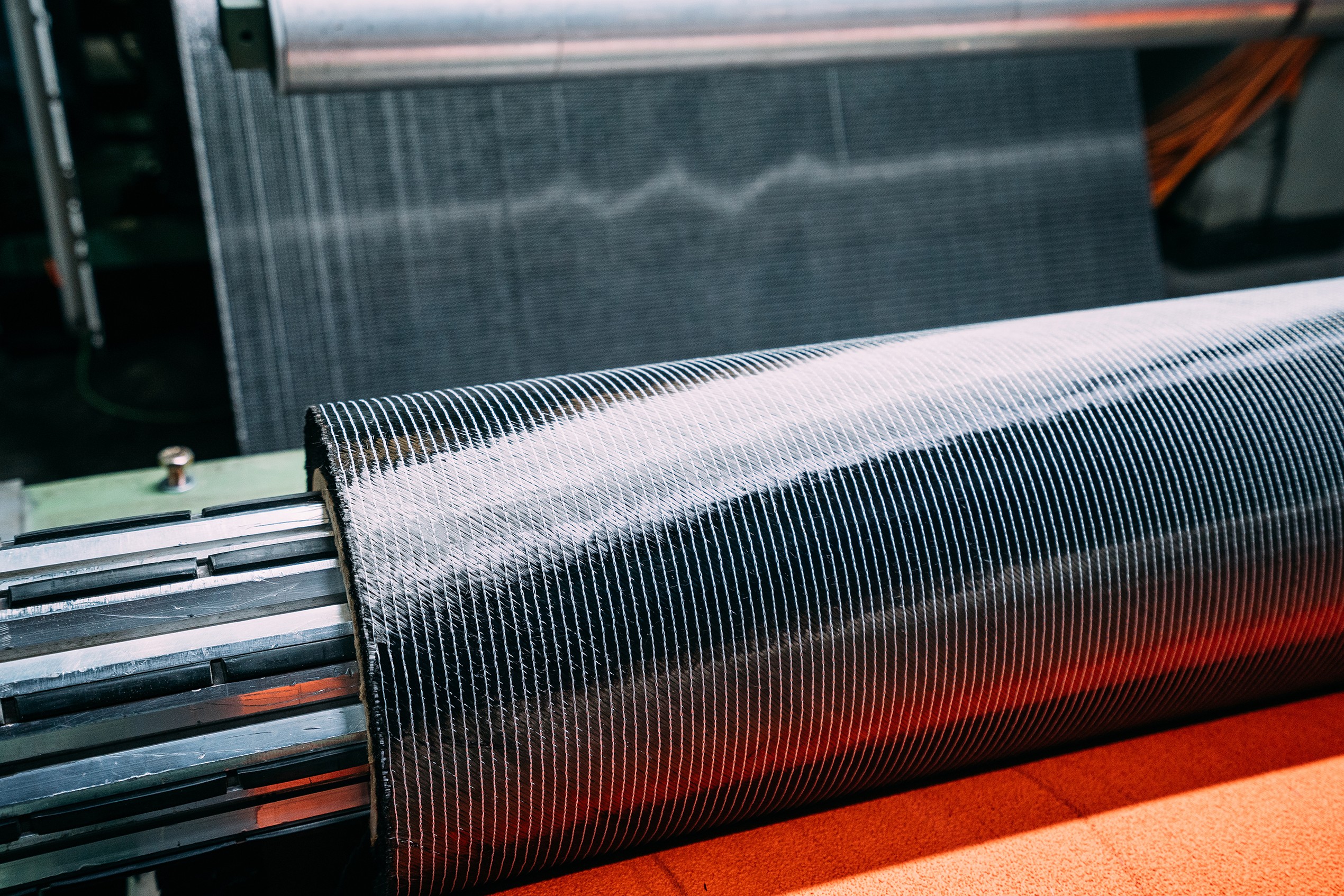

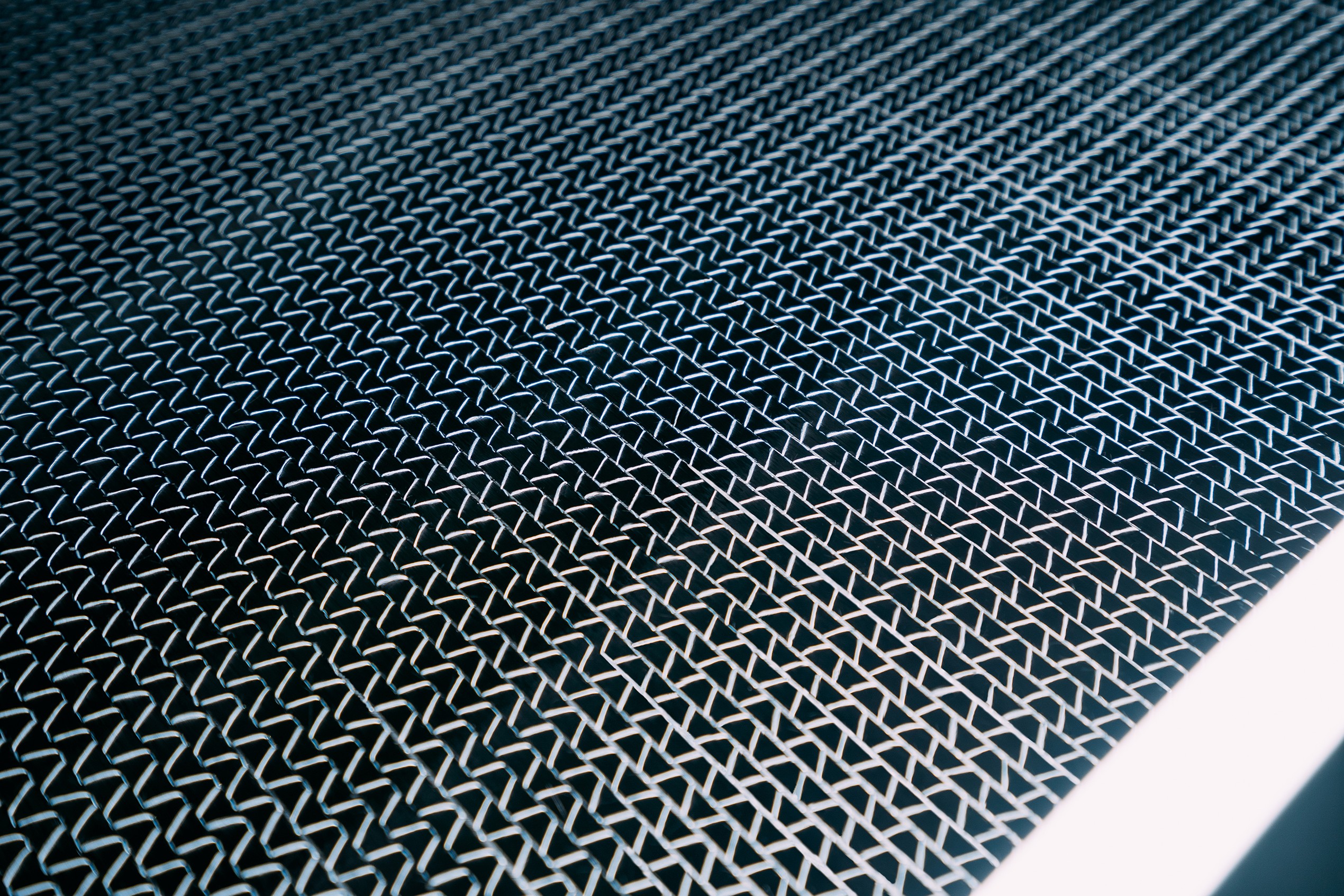

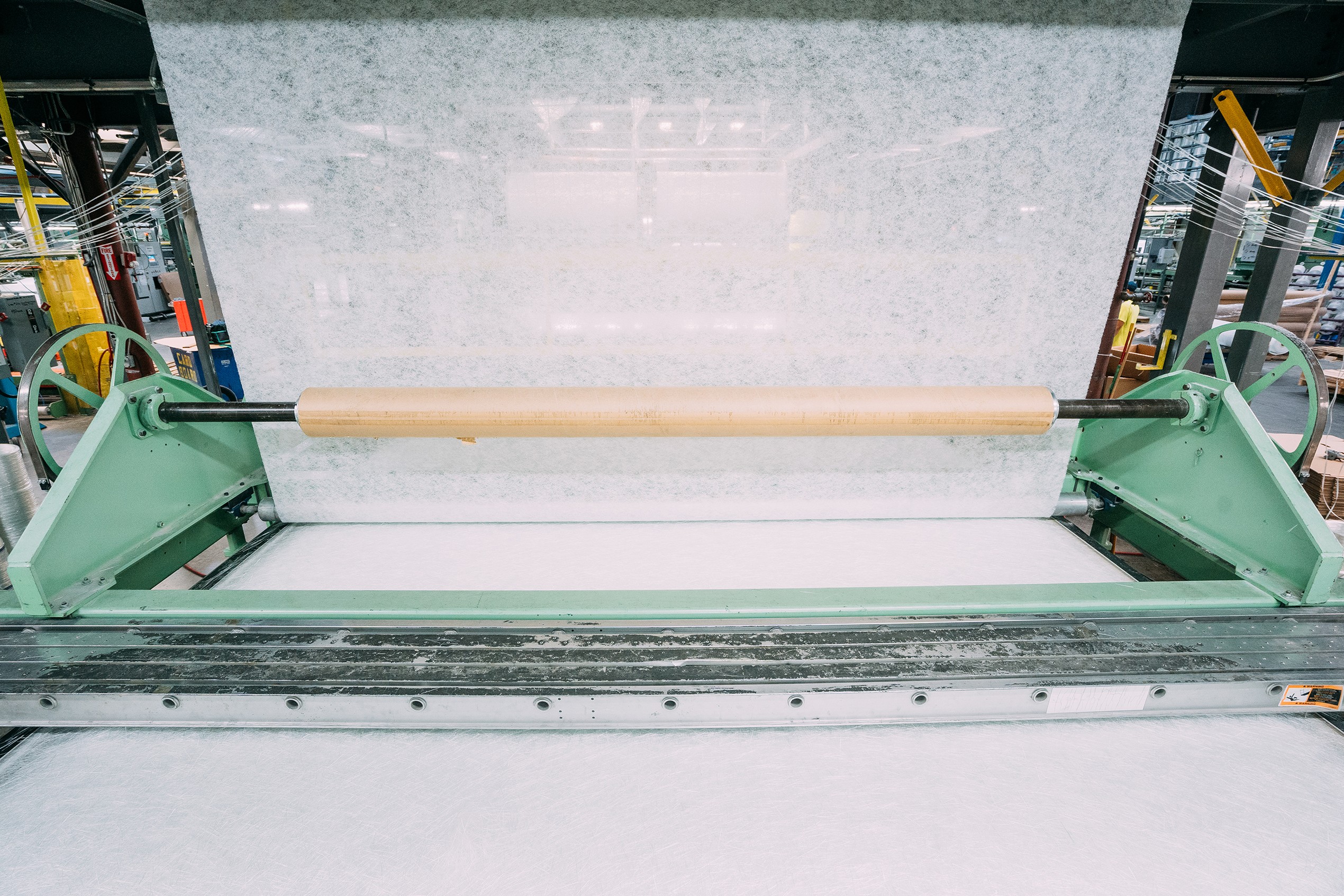

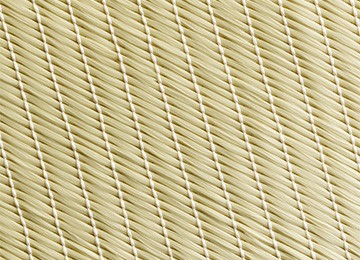

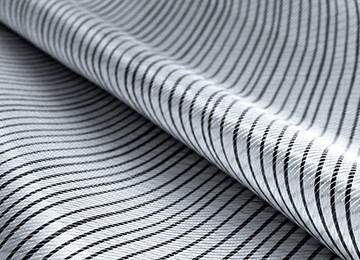

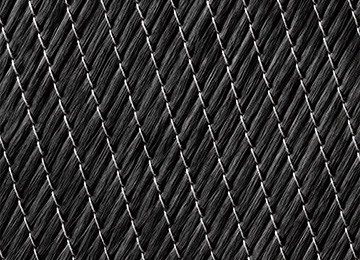

BASICS OF MULTIAXIAL FABRICS

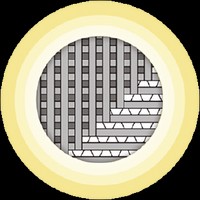

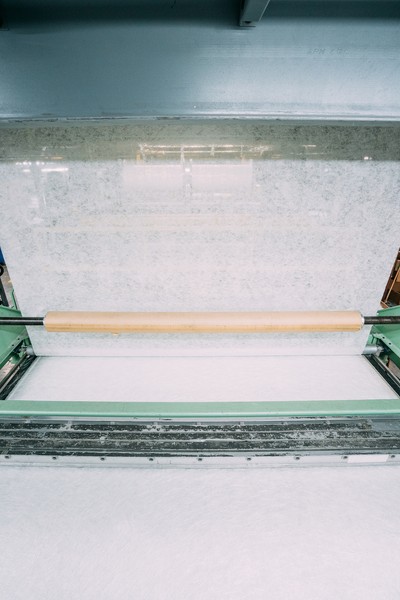

HOW A SAERTEX NON-CRIMP FABRIC (NCF) IS MADE:

The rovings are laid without fiber ondulations, thereby giving them a high mechanical load capacity. The special feature here is that it is possible to have multiple layers – with differing directional orientations. The individual layers are sewn together to form a textile reinforcement.

HIGHLY CUSTOMIZABLE: SAERTEX NON-CRIMP FABRICS

Whether fiber type, area weight, sewing, orientation or finishing: our products are individually configured for our customers and optimally adapted to various processes.

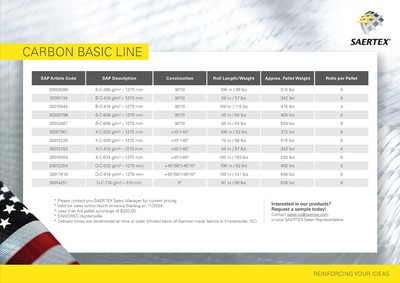

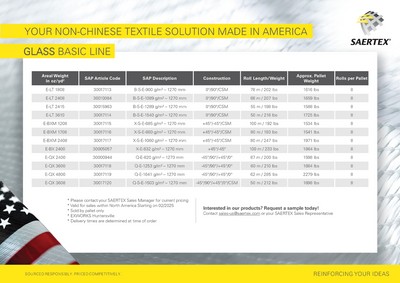

AVAILABLE FROM STOCK: SAERTEX BASIC LINE

The SAERTEX Basic Line is our popular standard product range with fast delivery due to available inventory in North America. The range comprises a portfolio of selected classic glass and carbon fiber fabrics.

Highlights

We at SAERTEX are one of the world´s leading manufacturers of textile reinforcements made of carbon, glass, aramid and natural fibers for lightweight construction. Our Non-Crimp fabrics (NCF) are used in the production of structural composites such as rotor blades for wind turbines, infrastructure, boats or load-bearing components in buses, trains, automobiles and more. Our wide range of high-quality solutions stands for innovation, quality and reliability - directly made in America.

SAERTEX USA further manufactures many specialty products that offer a variety of options for your project. These products can be customized to meet your specifications and offer benefits such as fast resin injection, reduced labor costs and time savings.

US Basic Line

Available from stock

The SAERTEX USA Basic Line is our standard product range with fast delivery due to available inventory in North America.

-

1.Economical: good products for a good price

For small and medium-sized purchase quantities, the articles of the Basic Line offer the most economical solution at SAERTEX. Good products for the best price, fast supply.

-

2.Available from stock – fast and reliable delivery

The products of the Basic Line are available from stock in America and can be delivered to our customers within a few working days. The products are appropriate for a variety of industrial, marine and transportation applications.

-

3.Quality: made by SAERTEX

We manufacture all products of the SAERTEX Basic Line with the proven SAERTEX quality standards directly in North Carolina.

-

4.Improved sustainability

Full truck loads, short distances to the customers, optimized packaging concepts - the Basic Line is a further step towards optimizing our range of products in terms of sustainability.

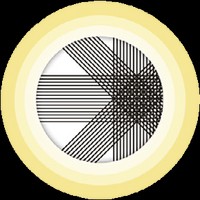

SAERTE.XTREME: THE 150-INCH MULTIAXIAL

Some visions only work in XXL format. Our new 150” multiaxial fabric enables you to bring them to life without making compromises – and with unprecedented efficiency and speed.

-

1.

Endless possibilities: With a width of up to 150 inches, the XXL fabric sets new standards. Due to their extreme width, the 150" multiaxials make it possible to cover new areas of application, e.g., building panels, trailer walls or cooling towers.

-

2.

Faster lay-up and enhanced efficiency: By using one large fabric, processes can be reduced and optimized. This saves you valuable time and resources.

-

3.

Versatility: Up to four layers can be processed simultaneously in different orientations and finished in various ways. This allows the production of fabrics adapted to your needs, even in extreme widths.

-

4.

Availability: We are the only producer of 150” multiaxial fabrics in the USA.

It’s time to expand your horizon: Let’s go to extremes!

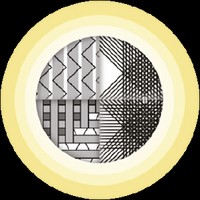

NEW SAERcore OPTIONS

Our solution for upgrading the composite manufacturing process from hand-lay up to closed mold

- High cycle time processing for structural fiberglass molding

- Optimized resin flow for RTM and L-RTM processes

- High drapeability to conform in complex molds

- Consistent thickness for stable composite manufacturing

- Corrosion-resistant fiberglass

- Class “A” finished surface and high quality standards

- Basic line available for short lead time

Special Features

- Application specific construction enhance functionality (e.g. print blockers or additional infusion mats)

- SAERcore MAX solutions for high-strength applications

- Reduce lay-up time by combining multiple plies into one material

- Compatible with multiple resin systems

- Fire-resistant and sustainable solutions available

- Customizable width (4” – 120”) and area weights (300gsm to 1800gsm)

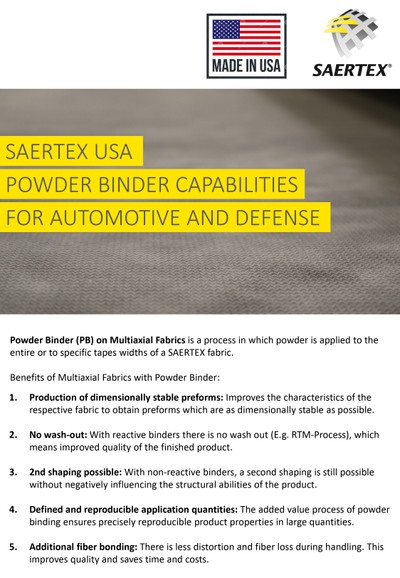

New Powder Binder finishing

Our new powder binder capabilities for high-value products with special characteristics.

Adding powder binder on Multiaxial Fabrics is a process in which powder is applied to the entire or to specific tapes widths of SAERTEX fabrics. Benefits of Multiaxial Fabrics with powder binder are the following:

-

1.Production of dimensionally stable preforms:

Improves the characteristics of the respective fabric to obtain preforms which are as dimensionally stable as possible.

-

2.No wash-out:

With reactive binders there is no wash out (E.g.RTM-Process), which means improved quality of the finished product.

-

3.2nd shaping possible:

With non-reactive binders, a second shaping is still possible without negatively influencing the structural abilities of the product.

References

Customers in the wind, aerospace, automotive, sports and boat building industries depend upon composites which gain in lightness, stability and corrosion resistance through the use of SAERTEX USA reinforcement materials made of glass, carbon and aramid fibers. With its products and the engineering know how, SAERTEX USA provides the basis for fascinating projects.

Our diverse customers are proof of our expertise and commitment in various fields. Would you like to learn more about how we operate successfully in these industries? Then don't hesitate and ask for our references.

Contact us

Discover our latest reference with SUNREZ

Structural components in transportation, infrastructure or wind energy face harsh conditions. That leads to damage, impacting reduced functionality and high maintenance cost. To reduce non-revenue times, it´s important to bring those critical components back into service as fast as possible and keep maintenance cost low.

THE SOLUTION:

“SUNREZ is one of the leading companies in America

to deliver solutions for field repair

with fiberglass patches. The beauty of field repair with our fiberglass patches lies in its

efficiency. It allows you to fix damaged parts cutting cost significantly, because of the

fast-curing

time and reduced labor costs. We develop these patches to be qualified by our customers and

using

high quality glass fiber multiaxials from SAERTEX.“ - Bret Tollgaard, CEO Sunrez Corp.

Distribution Partner

Northeast USA

Rhode Island

65 Tupelo St.

Bristol, RI 02809

Tel.: +1 401-396-5565

310 Friendly Rd.

PO Box 325

Morehead City, NC 28557

Tel.: +1 252-638-3553

385 Carr Drive

Brookville, OH 45309

Tel.: +1 800-838-8984

1100 Meyerside Drive

Mississauga, ON, L5T 1J4

Canada

Tel.: +1 877-773-7336

300 Apollo Drive

Lino Lakes, MN 55014

Tel.: +1 651-766-6892

Branch Office

301B N. Green Meadows Drive

Wilmington, NC 28405

Tel.: +1 800-234-7290

8450 Development Court

Wausau, WI 54401

Tel.: +1 715-842-0101

7360 Cockrill Bend Blvd

Nashville, TN 37209

Tel.: +1 615-218-3743

4902 Ampere Dr.,

Reno, NV 89502

Tel.: +1 775-833-4300

8260 Parkway Blvd,

Anjou, QC H1J 1N2

Canada

Tel.: +1 514-354-7644

4301 34th St N Ste B

St Petersburg, FL 33714

Tel.: +1 727-456-2410

834 W 25th St.

Norfolk, VA 23517

Tel.: +1 757-622-5914

South California area

2720 South Willow Avenue

Bloomington, CA 92316

Tel.: +1 909-877-8477

12200 Mt. Holly-Huntersville Rd.

Suite A

USA-Huntersville, NC 28078

Tel.: +1 · 704· 464 5998

Fax +1 · 704· 464 5922

Committed to serving customers around the world

Being close to our customers is important to us. We want to be right there – on-site –, when they need us.

That is why we have a number of reliable partners. Always ready to reinforce your ideas with multiaxials made in America.

WELCOME TO THE SAERTEX TEAM - YOUR FUTURE WITH US

Only those who are passionate about their work can be successful in what they do.

This is our motto at SAERTEX – and by following this motto we have become a leading international company in the development and production of high-tech reinforcing textiles made of glass, carbon, aramid and other high-performance fibres. To continue on our course of growth we need people who think just like us. Are you open to new challenges? Are you interested in actively working at a globally expanding company? If so, we’d very much like to get to know you.

Open job vacanciesContact

SAERTEX USA, LLC.

- 12200 Mt. Holly-Huntersville Rd.

- Suite A

- USA-Huntersville, NC 28078 (USA)

- Tel 704 · 464 5998

- Mail: sales-us@saertex.com